Waste-to-

Energy

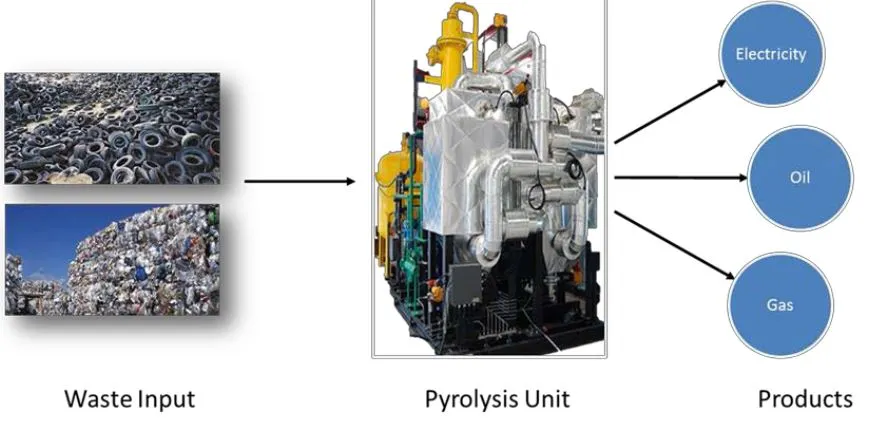

Tigacom Waste-to-Energy & CogenerationWorking with partnered Navitus Solutions, Tigacom Waste-to-Energy & Cogeneration develops waste-to-energy local and regional projects using integrated technology systems to generate fuels and electricity from the conversion of a wide range of high-volume carbon-based wastes. The system can produce electricity, synthetic oil, synthetic gas and carbon char returning value, along with drive and sustain agriculture, industry, and local economies. At the core of the system is the scalable EcoPyrolix system, an environmentally sustainable technology based on the commercially viable recovery of oil and gas energy and carbon char from readily-available, high-volume waste materials. The system produces no emissions from the processed waste materials and its ultra-low emission burners are designed to meet all international emissions standards. The continuous process EcoPyrolix systems are modular and skid-mounted and are easily transported and installed at any location. Units can be sized for projects ranging from 1 ton per hour and up to 500 tons per day, with larger custom systems also available. Typical waste material feedstock categories including:

- Tires (used passenger tires);

- Plastics (soft and hard plastics, electronic waste, auto-fluff, industrial plastics);

- Biomass (paper pulp, wood chips, agricultural green waste, cow and chicken manure, algae cake); and

- Municipal solid waste (MSW), excluding inert materials such as metal, stone, and glass.

- The system is self-sustaining and uses a portion of the gas produced to generate the requisite heat for the process. The remaining gas is used to run an electricity generator to supply marketable electricity.